Data storage company Seagate decided to integrate a rainwater harvesting system at its Media Research Center in Fremont, California to reduce demand on the municipal water supply and the impacts of stormwater runoff.

FACILITY BACKGROUND

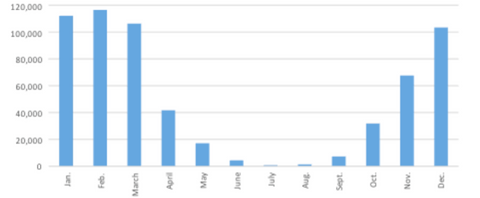

The facility is the former home of solar-panel manufacturer Solyndra, but Seagate purchased it in 2013 to house research and development projects. The facility has more than 62,000 square feet of roof area from which rainwater can be collected. With an average annual rainfall total of about 16 inches in Fremont, the facility has the potential to collect more than 580,000 gallons of rainwater each year (see Figure 1). Steven Deason, the Executive Director of Facilities for Seagate, wanted to reduce municipal supply-demand and create a sustainable environment for the software company’s research facility.

(from roof size based on average monthly precipitation in Fremont, CA)

RAINWATER SYSTEM DESIGN

The collected rainwater is used to supply nonpotable uses such as toilet and urinal flushing, scrubber makeup, and cooling tower makeup. The rainwater collected from the roof is filtered by two WISY WFF300vortex filters (see Figure 2), which remove particulates greater than 380 microns from the collected rainwater. The clean water then flows into one of two 29,700-gallon storage tanks, and the debris exiting the filter is carried to the storm drain. The clean water enters each tank through an 8-Inch Smoothing Inletthat directs the water flow upward, preventing any disturbance of the healthy biofilm that has developed at the bottom of the cistern as well as oxygenating the tank.

FIGURE 2: WISY WFF300 VORTEX FILTERS

Any particulate that has passed through filtration will either sink to the bottom of the tank or float on the surface of the water. Should the water reach a high enough level, an overflow line will prevent the storage tank from overflowing into the building as well as siphon small particulates floating on the water surface. (see Figure 3)

FIGURE 3: OVERFLOW LINE

The water is drawn by a 3-horsepower booster pump through a 2-inch WISY Floating Filter that takes water from 6 to 8 inches below the surface level. This prevents any intake of floating particulates at the top of the water level and ensures that the cleanest water is being used. The pumped rainwater then passes through a custom-fabricated purification skid provided by Rainwater Management Solutions.

The first stage of skid filtration is a bag filter that will eliminate particles larger than 1 micron. The water then goes through a carbon filter to eliminate any discoloration or odors. Finally, the water passes through an ultraviolet light that will disinfect it and eliminate any harmful bacteria. The water is then stored in a 500-gallon day tank, (see Figure 4), where it is then drawn by a duplex booster pump skid and sent through the facility as needed. The duplex booster pump skid (see Figure 5) incorporates a variable-frequency drive to lessen power demands and prolong pump life.

FIGURE 4: DAY TANK

FIGURE 5: DUPLEX FIGURE 4: DAY TANK BOOSTER PUMP SKID

The rainwater harvesting system integrates a domestic backup water line for use when rainwater levels are low. The domestic line has a solenoid valve (see Figure 6) that is controlled by the RMS-200 controller interpreting a digital input from a float switch inside the day tank to the right.

The three post-tank filtration elements are mounted on a skid (see Figure 7) along with an RMS Series 200 Controller, which monitors inputs and controls pump operation as well as enables the domestic backup system. A normally closed solenoid valve is opened when a float switch in the day tank falls below a set level, indicating that there is not enough water in the system.

FIGURE 6: SOLENOID VALVE AND AIR GAP

FIGURE 7: PURIFICATION SKID

CHALLENGES

Michael Shaw, the Startup General Foreman with Therma Corporation of San Jose, California, shared responsibilities for retrofitting the former Solyndra facility to meet Seagate’s needs. One of the challenges faced was adapting the existing piping to accommodate the rainwater system. The original roof drainage had to be identified, disassembled, and re-routed to the WISY WFF300 vortex filters, and the piping following the final stage of filtration had to be adapted.

“The recycled water supply line installation and its integration with the existing restrooms posed the biggest challenge,” Shaw explained. “The water supply line to the existing urinals and toilets had to be separated from lavatories. It required some major in-wall exploration to locate the point of connection in some areas.” One of the other challenges for the rainwater harvesting system is the months with low rainfall totals. Due to the decreased collection of rainwater, the domestic backup integration proved to be essential for the dry summer months.

David Crawford is the CEO and Founder of Rainwater Management Solutions in Salem, Virginia and the current President of the American Rainwater Catchment Systems Association (ARCSA). T. J. Smith is the Director of Technical Support and Sales and Casey Richey is an Inside Sales Representative with Rainwater Management Solutions.